1 Polishing

The more you polish, the lighter and finer the taste.

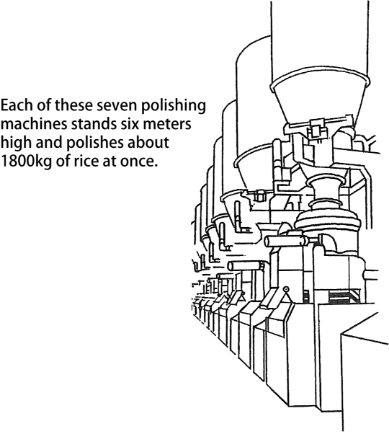

The first step in our brewing process is to polish the rice in our own polishing plant. We do this to remove the outer layers of the grain, which contain an abundance of vitamins, fats, and protein. It is especially important to reduce protein, because during fermentation protein breaks down into amino acids that can taste bitter. More polishing results in lighter, cleaner tasting sake.

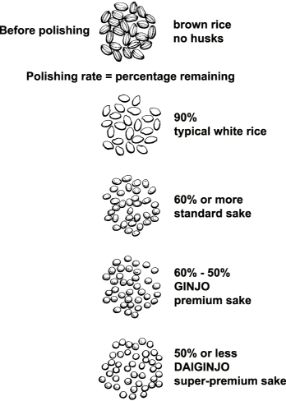

We know how much we have polished by comparing the weight of the brown rice before polishing to the weight after polishing. We indicate the polishing rate as a percentage remaining after polishing; for example, a polishing rate of 60% means that 40% of the rice was polished away, and 60% remains to be made into sake.

Note that the polishing rate is used to officially designate the grade of sake according to Japanese tax law. To be labeled DAIGINJO, super premium, the rate must be lower than 50% remaining, and to be labeled GINJO, premium, the rate must be between 50% and 60% remaining.

Polishing too fast breaks the kernels and over-heats the rice, so this work must be done slowly and gently. It takes more than 50 hours to achieve a polishing rate of 40%.